In the forging industry, material calculation and cutting are among the most critical stages of the production process. They directly affect raw material utilization efficiency, production cost control, and the final quality of forged products. This article provides an in-depth discussion of how scientific and well-planned material calculation and cutting practices can effectively improve material utilization, reduce loss rates, and ultimately enhance a company's economic performance and market competitiveness.

Before producing forged components, it is essential for forging plants to accurately estimate raw material requirements. Proper material calculation not only helps conserve raw materials but also ensures strict control over production costs. Excess material leads to waste, increased die wear, and higher energy consumption. Conversely, insufficient material, especially when inadequate forging allowance is reserved, can complicate process adjustments and significantly increase the scrap rate.

Before exploring methods to improve material utilization through optimized material calculation and cutting, it is necessary to understand the various factors that contribute to material loss. Only by identifying these factors can targeted measures be implemented to effectively reduce losses and improve production efficiency and economic returns. The key factors influencing material loss during the forging process are analyzed below.

In forging production, material losses mainly occur during cutting, rough machining, and finish machining. The amount of cutting loss is closely related to material properties, cutting tools, forging accuracy requirements, and the complexity of forging shapes. For example, materials with higher hardness tend to generate greater losses during cutting. Forgings with complex geometries, such as multiple curved surfaces or deep holes, also increase cutting difficulty and material loss.

Metal oxidation losses during heating, heat treatment, and quenching and tempering processes are significant and cannot be ignored. These losses are closely related to the type of furnace used, the number of heating cycles, and heating temperatures. Taking steel as an example, the first heating in a flame furnace typically results in a loss of approximately 2%–3% of the forging weight, while each subsequent heating causes a loss of about 1.5%–2%. Therefore, properly controlling heating temperature and frequency, as well as selecting appropriate heating furnaces, is essential for reducing oxidation losses.

The material utilization rate of forgings refers to the ratio of the weight of qualified forgings to the total material consumption. It is influenced by factors such as material properties, process methods, mechanical performance requirements, dimensional accuracy, and forging complexity. Generally, precision forgings have higher material utilization rates than conventional die forgings, while die forgings outperform open-die forgings in this regard.

For example, forging a 114-ton turbine generator rotor from a 190-ton steel ingot results in a forging material utilization rate of 60%. Blank material utilization refers to the ratio of the weight after rough machining to total material consumption, while component material utilization refers to the ratio after finish machining. In this case, after rough machining, the rotor weight is reduced to 86 tons, yielding a blank material utilization rate of 45.3%. After finish machining, the final component weighs 75 tons, resulting in a component material utilization rate of 39.5%.

The primary objective of material calculation is to determine billet diameter (or side length) and length, which serve as the basis for selecting and designing die forging steps and key die cavity parameters. Determining billet dimensions requires comprehensive consideration of forging weight, cutting losses, oxidation losses, material utilization rate, yield rate, and test forging losses.

By accurately calculating billet weight and combining it with material density, suitable billet dimensions can be determined. In addition, dimensional tolerances of raw materials have a significant impact on forging precision and must therefore be clearly specified and strictly controlled.

After identifying the main factors influencing material loss, it becomes clear that improving material utilization must begin with cutting optimization. Cutting is a critical step in forging production, and its accuracy and efficiency directly determine the smoothness of subsequent forging processes and overall material utilization.

For bar materials, continuous multiple cutting (such as sequentially cutting several small billets) can effectively reduce end waste. For plate billets, nesting optimization software can be used to plan cutting paths and minimize material loss. For example, when producing a batch of regularly shaped plate forgings, optimization software can precisely calculate cutting layouts to maximize material utilization.

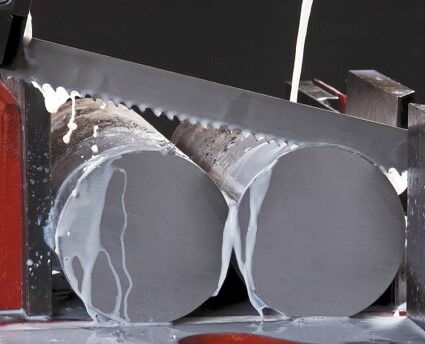

Advanced equipment such as CNC band saws, laser cutting machines, and plasma cutting systems are gradually replacing traditional abrasive wheel saws. These technologies significantly improve cutting accuracy (up to ±0.5 mm) and reduce kerf width by up to 30%, thereby minimizing cutting losses. Laser cutting machines, in particular, produce smooth cutting surfaces for high-precision forging billets, reducing the required machining allowance in subsequent processes.

Hot shearing, cold shearing, or high-speed cutting processes for bar materials can eliminate saw-cut waste and are especially suitable for mass production of small and medium-sized parts. For example, in the production of large quantities of small shaft forgings, high-speed cutting enables rapid and accurate billet preparation, significantly improving productivity while reducing material waste.

While cutting optimization is essential, it alone is insufficient to comprehensively reduce forging losses. Loss rates are influenced not only by cutting accuracy and processes but also by forging technology, equipment performance, operator skill levels, and quality control systems.

Forging parameters such as heating temperature, forging speed, and deformation degree must be strictly controlled to ensure forging quality. Improper parameters, such as excessive heating temperature or overly rapid forging, can lead to surface oxidation and internal defects, increasing loss rates. Die design and manufacturing accuracy also play a critical role; worn or poorly designed dies result in dimensional inaccuracies and increased machining allowances. Continuous process optimization and standardized operating procedures are therefore essential.

Equipment performance has a direct impact on forging loss rates. Advanced forging equipment provides more precise temperature control and higher forging accuracy. However, inadequate maintenance can degrade equipment performance over time, negatively affecting product quality. Regular inspection, maintenance, and timely repairs are essential to ensure stable equipment operation and reduced losses.

Operator expertise significantly influences loss rates. Skilled workers who fully understand forging processes and operational techniques can effectively prevent errors and defects. In contrast, insufficient technical knowledge or poor judgment can lead to operational mistakes and increased scrap. Therefore, enterprises should invest in systematic training and performance evaluation to enhance worker skill levels and responsibility.

Advanced inspection technologies and quality control systems enable real-time monitoring of forging processes, allowing issues to be detected and addressed promptly. Non-destructive testing (NDT) methods can identify internal defects, ensuring compliance with quality requirements. In addition, advanced machining technologies can improve efficiency and precision, further reducing machining allowances and material loss.

Residual materials after unloading should not be wasted. Instead, they should be classified and labeled according to material grade, specifications, and remaining dimensions, and prioritized for use in small forgings or maintenance parts. For example, leftover materials can be processed into small components such as washers or nuts, reducing waste while generating additional value for the enterprise.

A forging plant producing large turbine generator rotors serves as a practical example. By optimizing material calculation and cutting processes, the plant significantly improved material utilization. Billet dimensions were accurately calculated based on forging weight, cutting losses, and oxidation losses, and advanced cutting equipment was employed. During forging, heating temperatures and forging parameters were strictly controlled, die design was optimized, and flash volume was reduced. Equipment maintenance and worker training were strengthened to improve precision and quality.

As a result, the forging material utilization rate increased from 55% to 65%, while the loss rate decreased from 15% to 10%. This not only saved a substantial amount of raw material but also reduced production costs and enhanced overall economic performance.

Material calculation and cutting are critical to improving material utilization in forging production. Scientific material calculation enables precise billet sizing and reduces waste, while optimized cutting processes and advanced equipment further minimize losses. At the same time, enterprises must adopt a comprehensive approach encompassing forging process optimization, equipment management, worker training, and quality control. In today's highly competitive market, forging companies can only maintain a strong competitive position by continuously optimizing production processes and maximizing material utilization.