Rotary forging is a specialized forging process used to produce precision forgings and is widely applied on rotary forging machines. In simple terms, during the forging process, a tube or bar rotates and advances along its axis while being subjected to pulsating radial impact forces. Through this method, the cross-sectional area of the billet gradually decreases, ultimately forming precision forgings with either varying or uniform cross-sections along the axial direction.

The core of this process lies in the combination of rotation and radial impact. During rotary forging processing, the workpiece both rotates and moves axially, while multiple hammers are symmetrically arranged in the radial direction to strike the surface at high frequency. This unique forming method allows the metal to gradually take shape through numerous small deformations, ensuring high precision while enhancing material properties.

To understand the rotary forging process, it is essential to first recognize the core equipment that enables it, the rotary forging machine. Although these machines vary in appearance, their fundamental structure revolves around two key actions: radial impact and rotational feeding. Depending on equipment layout, drive method, and hammer configuration, rotary forging machines can be divided into several types, each with specific application scenarios and technical characteristics.

Rotary forging machines are primarily classified into vertical and horizontal types, each suited to different production needs:

Vertical radial precision forging machines are mainly used for forging shorter components. With the workpiece positioned vertically, clamping is stable, making them particularly suitable for short shaft parts that require high precision.

Horizontal radial precision forging machines are better suited for producing long forgings and offer clear advantages in automation. The horizontal placement facilitates automatic loading, feeding, and unloading, making them ideal for high-volume continuous production.

Horizontal precision forging machines can further be divided into mechanically driven and hydraulically driven types based on their power source:

Hydraulic precision forging machines are typically used in small steel plants. Their main advantage is relatively low equipment cost, allowing them to partially replace rolling mills for certain processes. With strong force and easy controllability, they are suitable for companies with limited equipment investment but requiring basic forging capabilities.

Mechanical precision forging machines are commonly used for billet opening of alloy steels and for forging bars, stepped shafts, and hollow tubes. Mechanical drives provide higher motion accuracy and faster speeds, making them ideal for applications demanding superior machining precision and surface quality.

After understanding the machine types and structures, mastering the working principle is key to grasping the essence of this technology. Rotary forging achieves precision forming by cleverly combining radial pulsating impacts with rotational feeding, creating unique metal deformation conditions.

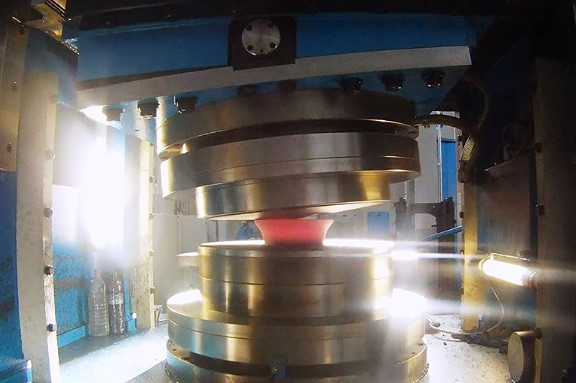

The working principle of rotary forging is both ingenious and efficient. The equipment is typically equipped with two or more hammers arranged symmetrically along the radial direction. These hammers perform high-frequency reciprocating radial movements, hundreds or even thousands of times per minute, continuously striking the workpiece. Meanwhile, the workpiece rotates and moves axially, undergoing radial compression and elongation under the pulsating impacts.

The process can be understood as follows: when the spindle rotates to the position where the rollers contact the sliders (mushroom heads), the dies move toward the center to close and strike the billet. As the rollers continue rotating away from the sliders, centrifugal force drives the sliders in the opposite direction, opening the dies and completing one forging cycle. Continuous spindle rotation repeats this action, applying pulsating forces that gradually reduce the billet’s cross-section and enable progressive forming, with metal flowing forward and backward along the axis.

Typical working parameters highlight the precision characteristics of rotary forging:

- Impact frequency: 180–1700 strokes per minute, with newer equipment exceeding 1000 strokes

- Single stroke: Only 0.25–1.5 mm per jaw

- Deformation amount: Small per strike, representing progressive forming

- Machining accuracy: Hot forgings can reach tolerance grades 6–7; cold forgings can achieve grades 2–4

- Surface quality: During cold forging, surface roughness can reach Ra 0.4–0.8 μm, sometimes eliminating the need for grinding

To meet these requirements, rotary forging equipment must achieve watch-level precision, resulting in complex but exceptionally high-performing machinery.

The importance of rotary forging in modern manufacturing stems from its integration of multiple technological advantages. These benefits extend beyond product quality to encompass production efficiency, material utilization, and energy consumption, making it a critical process in precision forming.

Rotary forging features pulsating loading and multi-directional hammering, both highly beneficial to deformation quality:

- Triaxial compressive stress state: Radial hammering from multiple directions places the metal under triaxial compression, improving plasticity and reducing radial tensile stress within the billet, thereby preventing cracks.

- Uniform deformation: Small, high-speed compressions reduce friction and resistance, allowing deformation to penetrate deeper into the material.

- Significantly improved plasticity: For low-plasticity alloys, pulsating loading can increase plasticity by 2.5 to 3 times compared to continuous forging. At frequencies above 1000 strokes per minute, metals can maintain high process plasticity, enabling cold forging.

The term precision forging is well deserved:

- Wide size range: Domestic radial forging machines can forge solid shafts up to Φ400 mm, hollow shafts up to Φ600 mm in outer diameter, and lengths up to 6000 mm. Roller-type machines can process solid parts from Φ150 mm to hollow parts with outer diameters up to Φ320 mm.

- High dimensional accuracy: Hot forgings achieve grades 6–7, while cold forgings can reach grades 2–4, and sometimes even grades 7–8.

- Low surface roughness: Cold forging can achieve Ra 0.4–0.8 μm with excellent roundness, occasionally replacing grinding.

- Superior internal structure: Uniform grain refinement and preserved metal fiber flow produce deformation strengthening effects.

Rotary forging delivers impressive productivity:

- High-frequency hammering: Hundreds or thousands of strikes per hour, with some products exceeding 150 pieces per hour.

- High automation: Modern radial forging machines support fully automated adjustment, loading, forging, overload protection, vibration cleaning, and exhaust removal, improving working conditions and simplifying operation.

- Fast processing speed: Forming a single profile may take only seconds, and most parts can be completed in under one minute.

- Quick changeover: Simple hammer shapes and strong adaptability enable rapid adjustments for different products, supporting both small and large production batches.

Another major strength of rotary forging is its wide material compatibility:

- Conventional materials: Suitable for various steels with good plasticity.

- Difficult-to-deform materials: Particularly effective for high-strength, low-plasticity alloy steels.

- Refractory metals: Capable of processing tungsten, molybdenum, niobium, tantalum, zirconium, hafnium, and their alloys—materials notoriously difficult to machine using traditional methods.

- Special materials: Applicable to extremely low-strength sprayed materials such as aluminum tubes clad with aluminum-nickel powder, as well as high-temperature sintered powders.

- Large deformation capability: Under triaxial compressive stress, metals can achieve plastic deformation levels of 30–40%, and even up to 70%.

The unique vibratory feed approach provides additional advantages:

- Reduced deformation resistance: Elastic recovery between compressions prevents resistance accumulation. Experiments show high-frequency vibratory feeding can reduce resistance by up to 40%.

- Improved lubrication: Intervals allow coolant lubricant to enter the deformation zone, forming an oil film that reduces friction.

- Extended die life: Lower resistance and improved lubrication significantly reduce wear.

Despite its many advantages, rotary forging has certain limitations that must be considered.

Complex structure: Requires skilled operators and maintenance personnel; routine maintenance can be challenging.

High cost: Precision forging machines involve substantial initial investment.

Strong specialization: Equipment is highly specialized with limited versatility, making it most suitable for dedicated batch production.

High raw material requirements: Billets must be uniform with minimal defects.

Complex process setup: Although changeovers are fast, initial parameter configuration demands extensive experience.

In industries such as automotive manufacturing, component designs often require special materials, structures, and mechanical properties. Traditional processes frequently become bottlenecks. Rotary forging helps overcome these constraints:

Breaking design limitations: Frequency- and amplitude-controlled axial forming makes previously impractical designs feasible.

Enabling complex structures: Components once difficult or impossible to manufacture can now be produced efficiently, enhancing functional performance.

Improving product quality: Technical indicators that were once difficult to guarantee become easier to achieve, fundamentally enhancing reliability.

Optimizing manufacturing processes: Reduces raw material waste, lowers energy consumption, increases efficiency, and decreases overall costs.

Thanks to its distinctive advantages, rotary forging has demonstrated strong adaptability across multiple industrial sectors, from traditional automotive components to advanced refractory metal processing.

- Solid stepped shafts: Including right-angle and tapered shafts such as steering spindles and drive shafts.

- Hollow shafts: Stepped hollow shafts and internally profiled materials that combine lightweight design with high strength.

- Specialized components: High-precision production of functional parts such as airbag cylinders and adjusting wheel drives.

- Stepped shafts for machine tools, tractors, and locomotives.

- Axisymmetric profiles, including tapered shafts and special cross-section parts.

- Thin-walled tubes for necking, reducing, and shoulder-type assembly.

- Gas cylinders: Necking processes for various cylinder types.

- Military products: Precision forming such as projectile shell necking.

- Special tubes: Mandrel forging enables precise control of inner diameters, shapes, and wall thickness.

Rotary forging shows unique value in machining difficult materials:

- Refractory metals: Forging rare metals like tungsten, molybdenum, tantalum, niobium, zirconium, and hafnium.

- Powder metallurgy materials: Forming high-temperature sintered powders.

- Composite materials: Processing sprayed materials such as aluminum tubes clad with aluminum-nickel powder.

As an advanced precision forming technology, rotary forging occupies an irreplaceable position in modern manufacturing due to its pulsating loading and multi-directional hammering mechanisms. It can process a wide range of materials, from conventional steels to refractory metals, and manufacture everything from tiny components to large shaft parts, achieving both high productivity and superior product quality.

With continuous advancements in automation, modern radial forging machines are becoming increasingly intelligent and flexible, improving working conditions and simplifying operation. Although the equipment requires significant investment and maintenance, rotary forging remains a highly worthwhile technology for specialized production focused on quality, efficiency, and material utilization.

For manufacturing enterprises, understanding and properly applying rotary forging not only enhances product quality and production efficiency but also provides a competitive advantage in processing new materials and complex structures, supporting the transition from traditional manufacturing toward precision and intelligent manufacturing.