Key Specifications / Features

- Model No.: PF-20251011-ASF-01

- Hits: 5

- Categories: Alloy Steel Forging Parts

- Tags: Hot Forged Kiln Tyre, Rotary Kiln Tyre, Alloy Steel Kiln Tyre

Detail Information

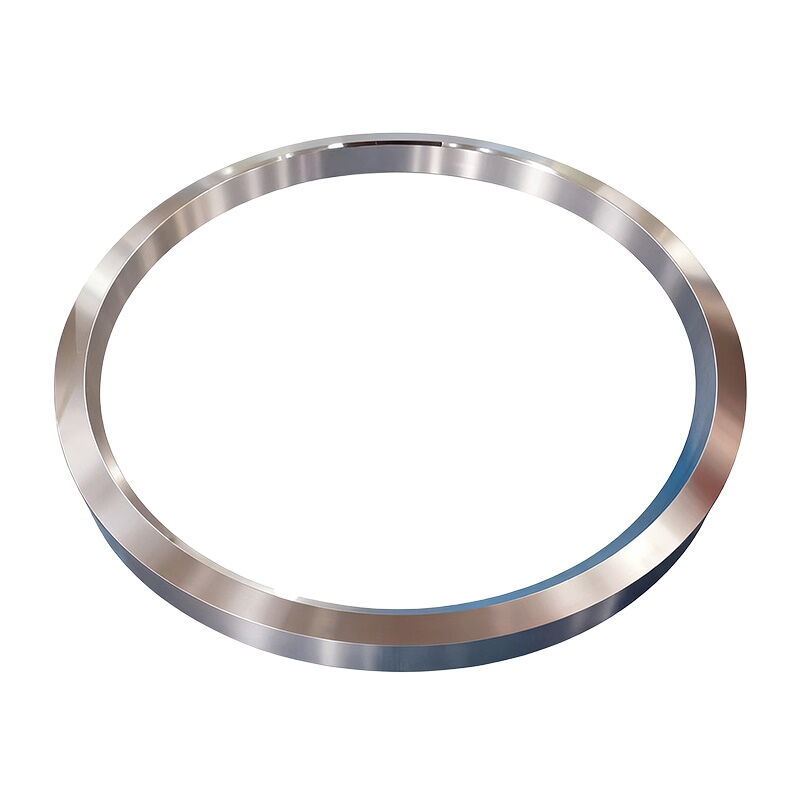

Product Name: Forged Rotary Kiln Tyre (Riding Ring) for High-Temperature Applications

Material Options: Alloy Steel 42CrMo, 35CrMo, 40CrNiMo, 20CrMnMo, 8620H, AISI 4140

Standard Compliance: DIN, ASTM, GOST, GB, JIS, ANSI, BS (Customizable)

Processing Method: Hot Forging → Rough Machining → Quenching & Tempering → Finish CNC Machining

Heat Treatment: Normalizing, Quenching & Tempering, Stress Relieving

Surface Treatment: Anti-Rust Oil Coating, Black Oxide, Phosphating

Forging Tolerance: ±0.01mm to ±0.1mm (Based on customer requirements)

Inspection & Testing: UT, PT, MT, Hardness

Customization: Fully Customizable per Drawing and Technical Requirements

Application: Cement Kilns, Lime Kilns, Metallurgical Kilns, Rotary Dryers, Metal Processing Machinery

Product Highlights

High strength, wear-resistant, and dimensionally stable

Essential for supporting rotary kilns and ensuring smooth operation

Suitable for extreme high-temperature applications in industrial kilns and metal processing machinery